|

"Hello Henry, |

||

|

|

|

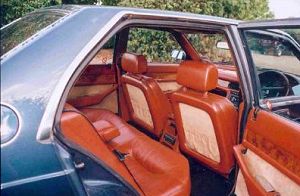

You can see that the car has 16" wheels, Zender side skirts and the MIE front and rear bumpers with 430 chrome cappings on top. It is a 425 but the front wings, front panel and headlights are from a 430. The bonnet is Karif. Also the 430SE(?) rear spoiler and number plate surround are on the back. I bought the car as a restoration project in 1992 and took the choice to update the appearance, as it needed new panels anyway! |

||

|

|

|

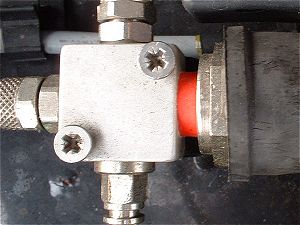

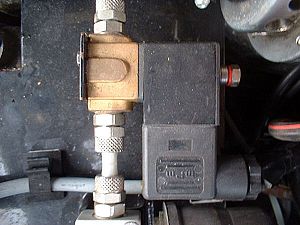

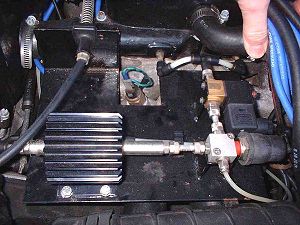

The wiggly round thing infront of the plenum chamber is an ERL 8BAR race water pump (www.aquamist.co.uk and see system 1S). This pumps water through a solenoid valve and a small manifold block to a pair of 0.4mm orifaces mounted on the front face of the plenum. It is set so that when the boost exceeds 10psi a water mist is injected at about 300ml/min flow. This STOPS pinking!! |

||

|

|

|

What do you think? |

||

|

| ||

|

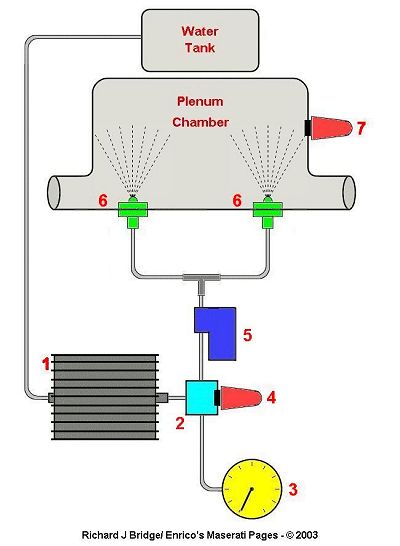

"Dear Richard, "Hi Enrico, "Hi again Enrico,  Simple schematic drawing of the water injection system |

||

The high pressure race version of the pump (1) pumps water into a small manifold (2) with a pressure switch (4) on it. This is set so that the manifold always has about 6 BAR of water pressure in it as read by a gauge on the dashboard (3). When the pressure is reached the pump is switched off and the pressurized water remains in the manifold waiting to be released. |

"Hello Enrico, |

If anyone would like more details and information about the water injection system, you can email Richard at richard(at)general-aviation(dot)net and I'll email it to you. |

|

||

|

To enter Enrico's Maserati Pages CLICK HERE! Copyright: Richard J Bridge/ Enrico's Maserati Pages - © 2003-2004. All rights reserved. |