| Nasty Shocks!!! | |

CAUTION: Maintenance work of this nature should only be carried out by a trained professional mechanic. |

|

Once all has been removed, secure the lower part of the shock in a vice. Either clamp the eye (rear shocks) or another part which does not involve clamping the main tube (fronts). DO NOT OVERTIGHTEN IN ANY CASE. |

|

|

|

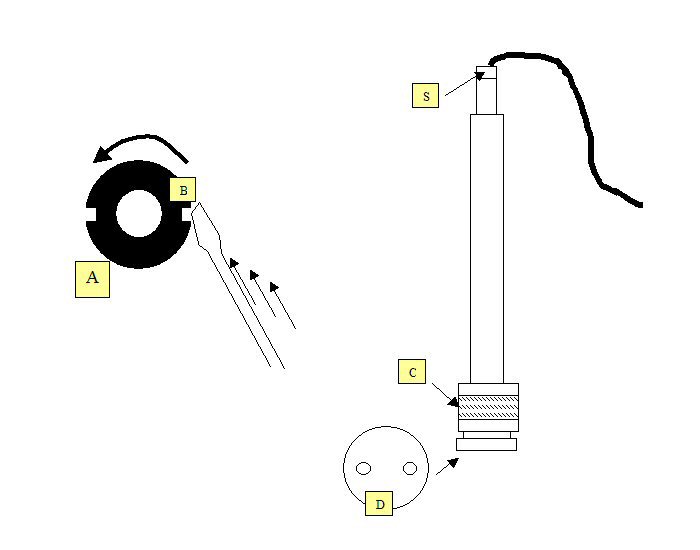

Turn the cap (A) where the chrome piston strut enters the shock to unscrew it. Use a tool similar to that used for fixing discs onto angle grinders/cutters. Unscrew by hand until you near the nitrogen used to pressurise the outer tube, coming out. Leave all the gas to escape before finally unscrewing the cap completely. Replace the various seals including the piston band (C) which is worn out should present a smooth surface as opposed to a textured surface. The washer with an "L" shaped fork coming off the side will engage with the little arm you can now see in the piston. The little arm is linked to the servo through some gearing and will move the washer round to cover some oil passages to increase the damping. When we select a softer damping rate, the servo will move the washer round to uncover the oil passages, hence enabling an easier oil flow past the piston. Make sure than when re-assembling all the washers in the pack, the washer which is allowed to turn (the one with the fork) can rotate freely from all holes covered to all holes uncovered. If not, then loosen the pack, adjust the position of the oil passahge washer and fasten up again. Repeat above operations in reverse to fit washer pack back into piston. Be sure the fork engager with the lever arm connected to the servo. If fixing the shock damping in 1 position, align the lever arm to a position which gives the desired damping (the more holes the fork-washer covers, the stiffer the damping). Inthis case, when you have re-fitted all the shocks, do not re-connect the wires to the control box. |

|

|

|

|

|

||

|

To enter Enrico's Maserati Pages CLICK HERE! Copyright: Enrico's Maserati Pages - © 2005. All rights reserved. |