Many

enthusiasts will already have seen, at Goodwood, Castle Combe and Snetterton, towards the end of

last season, a beautiful new Maserati sports car in the hands of Roy Salvadori. This car, of the

latest type, is the property of enthusiast, 44-year-old S. G. Greene, director of Gilbey

Engineering company (which manufacture precision components for - amongst other things - car

suspension dampers and fuel-injection equipment), and his co-director, Norman Osborne. Although

Sydney Greene is himself debarred from active racing by the loss of one arm, he is determined

to run a racing team, and eventual plans include the manufacture of a Grand Prix car to carry

the colours of this country in international competition. Meanwhile, to build up the organization

and gain experience, he has imported the Maserati sports car to be followed by a 2.5-litre Formula

1 GP machine from the same factory. Roy Salvadori will once more drive for the team, and a very

full programme of both sports and racing car events is envisaged.

Principal construction details; the tubular chassis frame, on to which

is welded the tubular body framing, forms a very rigid structure.

The sports Maserati is a very interesting machine, and is in basic design but

little different from the 1953 Formula 2 GP Maserati. The engine, especially, is merely a

slightly detuned version of the alcohol-burning racing car, with a reduced compression ratio to

allow for the use of normal first grade fuels. Like its racing counterpart, the car is built on

a tubular chassis frame, with coil springs and wishbone independent front suspension, and quarter-elliptic

leaf springs supporting the live rear axle, which has an interesting location by radius rods.

The engine is a six-cylinder, slightly over-square in bore-stroke ratio (76.5mm X

72mm, giving 1988 cc); the cylinder block and crankcase are cast in light alloy, as is the

detachable cylinder head. Dry cast iron liners form the cylinder bores. The steel crankshaft is

carried in seven main bearings, and the connecting rods, with H-section stems, are of nickel-chrome

steel. The combustion ratio is 8.5 to 1. The combustion chambers are hemispherical, the inclined

valves being actuated from the twin overhead camshafts through pivoted finger. Each camshaft is

carried in four bearings, and gear driven through a straight-toothed gear train at the front of

the engine.

When the spare wheel (not shown) is in place above the rear-mounted oil

tank,

there is room in the locker for no more than the proverbial toothbrush.

Lubrication is on the dry sump principle, the pressure pump being located inside

the crankcase. The scavenge pump, externally mounted, returns the oil to the rear-mounted five-gallon

oil tank via an oil radiator positioned low in the nose of the car; both pumps are of convential gear

pattern, the normal oil pressure being in the region of 70 lb per sq in.

Two 14 mm sparking plugs per cylinder are used, situated on the longitudal centre

line of the engine. These are fired by two seperate coil ignition systems, one Marelli distributor

being driven from the rear of the exhaust camshaft, the other by skew gears from an idler gear driven

from the crankshaft nose on the right side. Incidentally, the one is timed to fire two degrees in

advance of the other, this apparently gives slightly increased power output; no manual advance

and retard control is provided, the normal centrifugal automatic operation being used.

Three horizontal double-choke Weber carburettors, type 40DC03, are used giving

the effect of one carburettor per cylinder: the fuel feed is by two Fimac electric pumps mounted

on the right side of the cockpit. Two swept three-branch exhaust manifolds conduct the gases into

the twin two-inch diamter exhaust pipes, each of which incorporates a small expansion box by way

of a silencer.

Note the three double - choke Weber carburettors,

the dual ignition from two

distributors, the twin V-belt dynamo drive

and the universal jointed steering column.

The dynamo is driven from an extension of one of the intermediate timing gear

shafts by twin V-belts, and carries the centrifugal water pump on its rear end. The water is circulated

simultaneously and in carefully planned proportions to ports on the left hand side of the cylinder

block and six ports in the cylinder head above the exhaust valves (the latter arrangement by a

somewhat sinuous pipe layout to and up the back of the engine).The water offtake is by a

six-branch manifold, also on the upper face of the head, above the inlet valves, and thence to

the top of the radiator.

Power is transmitted from the engine through a dry twin-plate clutch to the

unit-mounted four-speed gear box. First and second speeds use constant-mesh helical gears, third

and top being synchromesh engaged. A neat remote control gear lever, short and straight, lies

conveniently to the driver's right hand (the car is, of course, equipped with left-hand driving

position). A small diameter propellor-shaft, with simple robust Hooks-type universal joints at

each end, leads to the hypoid bevel final drive unit, the casing of which is a light alloy casting

with a heavily finned sump. The axle is built up, a flanged tube being bolted to each side of

the central casing.

Twin electric fuel, pumps are bracketed in the right side of the cockpit. The

propellor - shaft runs

above the central tubular cruciform chassis member; the

practical and effective door lock and

reverse rear stop are other noteworthy details.

Basically, the chassis frame consists of two main steel

tubes, each of 3in diameter, swept inward at the front and up and over the rear axle. There are

two main central cross members, each of 2.375in-diameter tube, and two subsidiary tubular cross

members at the rear. The front cross member is a swept fabricated box section, the ends of which

are jointed at the top by another 2.375in-diameter tube, and the steering box mounting bracket

is incorporated in this on the left side. Two longitudinal tubes welded between this and the first

central cross tube carry the engine mountings.

A subsidiary framework of 1in-diameter tubes is welded to this basic structure

and forms the basis of the body framing and bulkhead, as well as contributing to the rigidity of

the whole frame. The remainder of the body framing (all of the steel tube, welded in position) is

of 0.5in diameter.

Front suspension is by double wishbones and

coil springs, an anti-roll bar being

linked to the

lower wishbones. The front brakes are radically

finned, thin discs

being riveted to their faces to complete a series of ducts for

centrifugal air extraction.

The front suspension is independent, by coil springs and

wishbones, the olwer wishbone being appreciably longer than its upper counterpart. An anti-roll bar

is fitted , as are Houdaille hydraulic dampers. The wishbones are jointed at their outer ends by a

forged king pin post, the pin being held solidly in its boss and the stub axle fork bushed to rotate

on its extremities. The steering arms are swept forward, one long and one short track rod coupling

them to the forward-facing drop arm on the steering box; this must result in a geometric inconsistency

on one side (probably the right), but no ill effects can be felt and the handling qualities of the car

are exceptionally good. The steering column incorporates two universal joints, and is topped by

a light and beautiful steering wheel cut from solid alloy plate, with a split 15in-diameter wooden

rim, formed to provide finger grips on its underside.

Front suspension is by double wishbones and

coil springs, an anti-roll bar being

linked to the

lower wishbones. The front brakes are radically

finned, thin discs

being riveted to their faces to complete a series of ducts for

centrifugal air extraction.

The rear

axle is located by tubular radius rods pivoted above its centre at each end and running forward

to frame mountings, and by a cross-braced tubular A-bracket, the legs of which are frame mounted

and almost span the front width, while the apex contains a socket surrounding a ball which depends

from the centre of the axle casing. Thus the axle is, in effect, swung on a parallelogram, while

lateral location is afforded by the triangular stiffness of the A-bracket. A quarter-elliptic leaf

spring, bolted to a welded bracket close to each main frame tube, is shackled at the rear to each

end of the axle casing. As at the front, an anti-roll bar and Houdaille hydraulic dampers are fitted.

The front ventilated and finned drum brakes.

The cast

aluminium brake back plates each boast four integral air scoops, two facing forward and two rearward.

The light alloy drums are pierced for cooling, but whereas the rear drums are are circumferentially

ribbed, those at the front have transverse ribs, a dished aluminium plate being riveted to the

outside of each drum. This tends to extract air from the holes in the drum face, and, in fact,

the rear air ducts are blanked off and not in use. Lockheed hydraulic opration is used for the

brakes, the hand brake (on the rear wheels only) being cable operated.

Splined centre-lock hubs are in conjunction with wire wheels; the normal tyre

size is 6.00 - 16in, although tyres of 6.50in section can be used at the rear to obtain a higher

gear. Five alternative axle ratios are available (4.22, 4.445, 4.74, 5.00, and 5.25 to 1), but the

alternative tyre size provides in effect, a means of splitting these gaps. Pirelli Corsa (racing)

tyres are at present in use.

Fuel is carried in a single large tank immediately behind the seats: this has a

capacity of 27.5 gallons, and is internally baffled to minimise surge. A large quick-action filler

cap protrudes through the body behind the passenger. Behind the fuel tank comes that of the oil

and what little locker space remains is occupied by the spare wheel. The battery, at one time

carried in the locker, is now mounted athwart the right side main chassis tube just behind the

engine, the main leads thus being kept short.

The simple but functional dashboard.

The body is panelled in light alloy of approximately 14 swg and has beautiful

and flowing lines with a minimum of unecessary decoration. Two bucket seats are fitted directly

on to the chassis frame. All the controls are well placed and well spaced; a central throttle pedal

is used, as on most Italian racing cars (simultaneous heel-and-toe operation of throttle and brake

is more easily accomplished with this layout). The instruments are kept to a minimum, being

confined to a rev counter, oil pressure gauge, and oil and water thermometers. A one-piece full

width Perspex windscreen spans the scuttle; incidentally, the lid of the engine compartment,

which lifts off completely, is secured by four quick-action catches. The two tiny doors are locked

by the simplest type of hook and peg fastener which, however, cannot come undone accidentally.

Altogether this Maserati sports car is a most desirable property, the sight -

let alone sound - of which will make any enthusiast's mouth water. With a power of 165 bhp (at

6750 rpm) on a compression ratio of 8.5:1, allied to a dry weight of 13.5 cwt, its performance

is a match for that of almost any sports car regardless of size or origin.

The beautifully proportioned A6GCS/53 with coachwork by Medardo Fantuzzi.

| A6GCS serie II Technical specification |

| Engine |

Front engined 6-cylinder in line |

| Bore and stroke |

76.5mm x 72mm |

| Cubic capacity |

1985.6 cc |

| Compression ratio |

8.75:1 |

| Distribution |

DOHC with 2 valves per cylinder |

| Induction system |

Normally aspirated with No 3 Weber

40DCO3 carburettors |

| Power output |

170bhp @ 7300 rpm |

| Ignition |

Double with Marelli ST65DTEM distributors(1952-53) |

| Lubrication |

Forced by pressure and scavenger pumps |

| Cooling |

Water cooled forced by centrifugal pump and oil cooler |

| Gearbox and clutch |

4-speed and reverse - dry twin-plate

plate |

| Transmission |

Rear wheel drive |

| Chassis |

Tubular structure with longitudinal and cross

members |

| Front suspension |

Independent with coil springs and

Houdaille hydraulic shock absorbers and anti-roll bar |

| Rear suspension |

Rigid axle with longitudinal leaf springs

and

Houdaille hydraulic shock absorbers and anti-roll bar |

| Steering |

Rack and pinion |

| Brakes |

Hydraulically operated drum brakes

(diameter front 328x60 mm and rear 290x50 mm) |

| Wheels |

Wire wheels 4.50 x 16 |

| Tyres |

Pirelli front 6.00 x 16 |

| Wheelbase |

2310mm |

| Wheel track |

Front - 1335mm / Rear - 1220mm |

| Dry weight |

740 kg |

| Bodywork |

Two-seater barchetta, berlinetta and spider |

| Overall dimensions |

Length - 3840 mm / Width -

1530 mm / Height - 860 mm |

| Maximum speed |

235 kph / 147 mph |

|

|

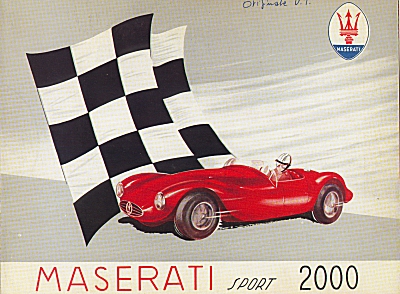

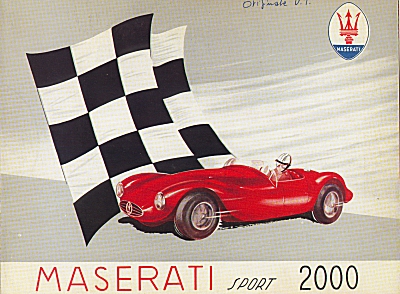

The sales brochure for the A6GCS/53 advertised as the 'SPORT 2000'.

This is a scan of the facsimile from the contents of the

'Archivio Maserati'

A MUST FOR THE MASERATISTA. | |

| |

|

|

|

To enter Enrico's Maserati Pages CLICK HERE!

Copyright: Enrico's Maserati Pages - © 2000-2004. All rights reserved. |

|